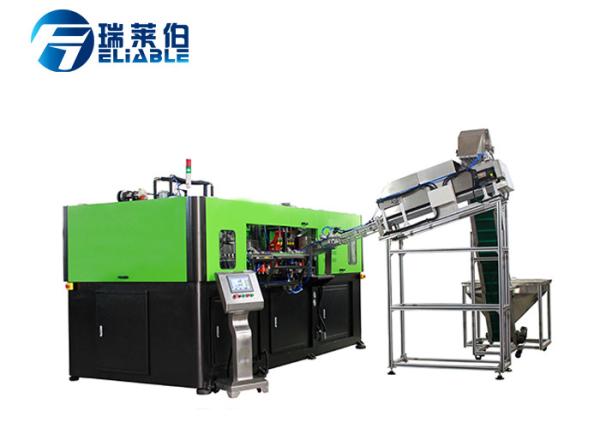

Product Description

RM series is one kind of two-step automatic PET bottle blow

moulding machine,which is suitable for blowing any shape of PET

bottles such as carbonated water bottles, water bottles, juice

bottles, oil bottles, cosmetic containers,etc.

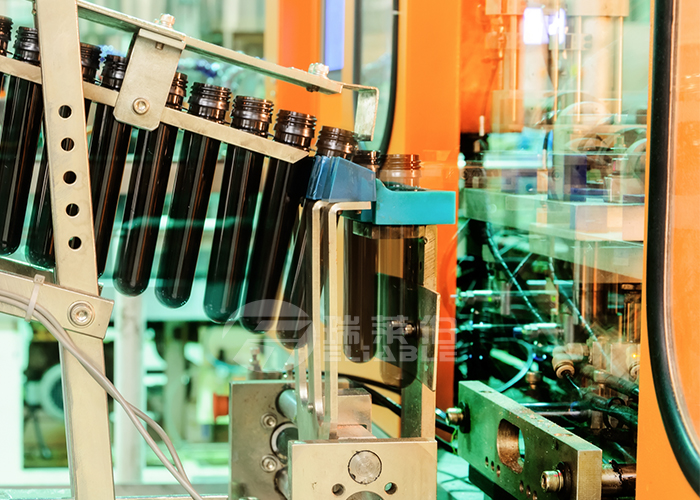

1.The machine adopts human-computer interface to control the whole

working procedures, auto-loading, auto blowing, auto dropping.

Action cylinders are all assembled with magnetic induction

switches.Connect with PLC to control every step and test every

cylinder. Next action will continue after the former step done, If

former step is not finished, alarm automatically and do not work.

PLC displays problem position.

2.Fast speed, accurate position, smooth action.

3.According to special demand, adopt cross double crank pressed

clamping, with strong clamping force. Mould open stroke can be

adjustable according to the bottle size to save the time.

4.Far infrared heater lamps have strong penetrations , preforms are

heated uniformly while rotating, PLC or electronic pressure

adjustor controls each group of temperature separately.

5.Particular pre-heater design makes preform close while heating.

Change space, shorten heating tunnel and reduce energy consumption

according to the bottle size while blowing.

6.The air supply system consists of slight blow, high pressure

blow, low pressure actions, to supply enough air for different

products.

7.Special recycling installation for high pressure air reduce the

energy consumption.

8.Operation consists of manual and automatic procedure, manual

operation for assembly and test, automatic operation for

production.

9.Production workmanship process is fully automatic to make best

quality and pollution-free. it holds less investment, high

efficiency, easy operation, simple repair, safety etc.

MATERIAL OF THE MACHINE AND MOLD ASSESSORIES

1)Raw plastic mould steel and BeCu imported from Germany, quick

heat conduction and dissipation to make rapid cooling of the caps

therefore higher productivity.

2)High precision of mold accessories to make good coordination of

each other.

3)Technology adopts nice heat treatment so as to achieve external

wear-proof and no deformation of internal structure.

4)Special coating process after heat treatment to make abrasion

resistance and increase the mold life.

ADVANTAGES

1)Shorter cycle time, 14 circles/minute (save time)

2)Less energy consumption, lower production temperature(save energy)

3)High productivity, triple capacity than injection machine(save cost)

4)Eco-friendly, caps will not decompose(save resource)

5)Low cost, each cavity is independent for maintenance(save cost)

6)One can operate the machine instead of several workers (save manpower)

7)Adopts hydraulic runner which advantage is avoid leaking oil,

cooling water runner to cool caps and devise rapidly, reduce

abrasion and increase mold life. (save cost)

Technical Data

| ITEM | | Unit | RM-4000HF |

| Capacity | Theoretical output | Pcs/h | 6500 |

| Product | Volume | L | 1.5 |

| Max.height | mm | 360 |

| Max.diameter | mm | 105 |

| Mould | Number of cavities | / | 4 |

| Mould plate dimension (L*H) | mm | 780*360 |

| Mould thickness | Mm

| 190 |

| Mould opening stroke | mm | 110

|

| Electrical system | Power | KW | 220-380V/50-60HZ |

| Total power | KW | 35 |

| Heating power | KW

| 32 |

| Air system | Operation Pressure | Mpa | 0.8-1.0 |

| Action Air Consuming | m3/min | ≤1.6 |

| Blowing Pressure | Mpa | ≤4.0 |

| Blowing Air Consuming | m3/min | ≤4.8 |

| Machine | Main body dimension(L*W*H) | M | 4.4*1.45*2.0 |

Main body weight

| KG | 3200 |

| Preform Autoloade(L*W*H) | M | 1.6*0.85*2.2 |

| Preform Autoloader weight | KG | 200 |