1. Product Introduction

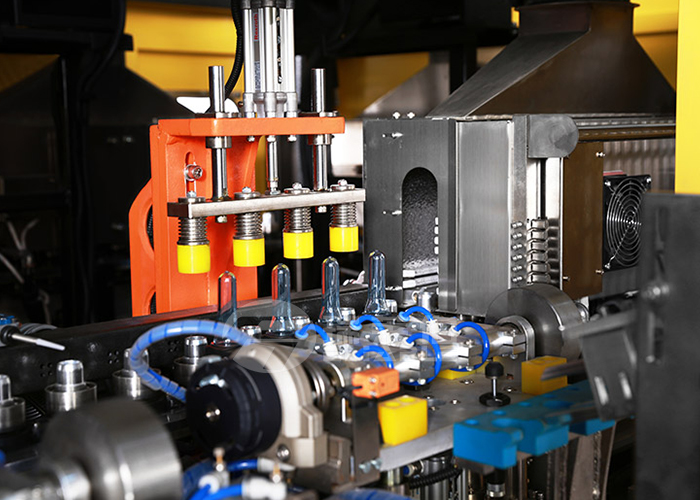

RM series Automatic Plastic bottle blow molding machine is suitable

for producing PET plastic containers and bottles in all shapes. It

is widely used to produce the carbonated bottle, mineral water,

pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot

fill bottle etc.

2. Product features

a. High speed capacity

Integrate movement of mold-opening and bottom mold elevating in one

movement, equipped with high speed servo driving system which greatly shorten

the cycle of blowing and increase the capacity.pet bottle blowing machine price

b. Servo motor system

The servo motor driven stepping system and mold clamping system

have improved the speed, flexibility and accuracy of blowing.

c. Modularized design conception

Adopting modularized design concept, to make it convenient and

cost-saving for the maintenance and changing spare parts.

d. Power saving

Compared with the conventional blow molding machine, it can save

more than 30% electricity consumption. The whole mechanism works speedy, accurately, stably and flexibly.

Meanwhile, it is energy efficient and environmental safe.

e. Small space occupation

The simple slide-in way of mold mounting makes it possible for the

operators to change molds easily within 30 minutes. The man-machine interface is highly automated and easy to operate.

The compact machine occupies a smaller area.

2. Advantage

1.Smooth production process from motor drives controlled by PLC

intelligent system.

2.Easy and flexible control operation realized by control system

developed by Tech-Long's R&D department.

3.Constant product quality coming from innovative technology that

allows Independent temperature control and parameter. setting of

each stretch blowing station.

4.Low noise from usage of deadening panels and few mechanical

transmissions.

5.High sanitary level provided by usage of enclosed blowing space.

6.Great visibility of whole production process and easy to access

to every part of the machine through shockproof doors.

7.Multilanguage system (English & Chinese); the selection of the

language can be carried out while the machine is working.

8.Remote assistance for self-diagnostics and updating necessary

software.

9.Lower production costs by reducing compressed air consumption,

which realizes from optimizing air flow and process stages.

10.Quick and simple mould change over due to lightweight moulds

with easy locating and fixing system.

Technical Data

| ITEM | | Unit | RM-4000HF |

| Capacity | Theoretical output | Pcs/h | 6500 |

| Product | Volume | L | 1.5 |

| Max.height | mm | 360 |

| Max.diameter | mm | 105 |

| Mould | Number of cavities | / | 4 |

| Mould plate dimension (L*H) | mm | 780*360 |

| Mould thickness | Mm

| 190 |

| Mould opening stroke | mm | 110

|

| Electrical system | Power | KW | 220-380V/50-60HZ |

| Total power | KW | 35 |

| Heating power | KW

| 32 |

| Air system | Operation Pressure | Mpa | 0.8-1.0 |

| Action Air Consuming | m3/min | ≤1.6 |

| Blowing Pressure | Mpa | ≤4.0 |

| Blowing Air Consuming | m3/min | ≤4.8 |

| Machine | Main body dimension(L*W*H) | M | 4.4*1.45*2.0 |

Main body weight

| KG | 3200 |

| Preform Autoloade(L*W*H) | M | 1.6*0.85*2.2 |

| Preform Autoloader weight | KG | 200 |