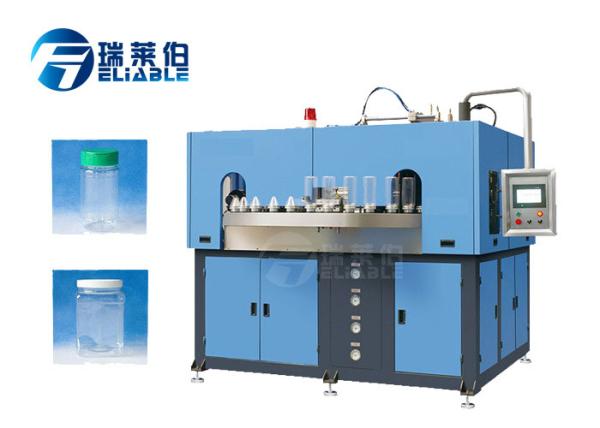

500ML Dried Food PET Bottle Blowing Machine 1000BPH Schneider Brand

With 1 Cavity

Flow chart

High Pressure Air Compressor -- Air Tank -- Air Fiter -- Air Dryer

-- Low Pressure Air Compressor -- Air Fiter -- Full Automatic Blow

Moulding Machine -- Mould -- Water Chiller

Introduction

1.Touch screen control and temperature adjustment make it easy to

blow different bottle type temperature regulation.

|

2.Its servo transmission system has high positioning accuracy, fast

and stable speed, good reliability, no gas source saving energy,

low maintenance cost, and the tension rod is controlled by servo

motor.

|

3.Bottle blowing machine has the advantage that can be segmented

stretching, bottle embryo location and first, to ensure that the

stretch when the bottle embryo verticality, second drawing again,

to ensure that every bottle embryo tensile uniformity and

consistency. Fast stretch and accurate position.

|

4.The bottle blowing machine is used for PET water bottle, hot

filling bottle, steam drink bottle, edible oil bottle, pesticide

bottle and so on.

|

5.Bottle blowing machine adopts servo control system, which has the

characteristics of stable and reliable structure, fast and stable,

easy to maintain, convenient and convenient for mould, and meets

the need of continuous production on-line.

|

Specifications

| 1. CE Certificate |

| 2. Different Shape Bottle |

| 3. Double/Single Statio |

System Introduction

| 1. Exploded bottles ejection unit |

During the blowing process, if the bottle burst, it can be

automatically removed. This prevents the bad bottles into the

filling machine.

| 2. HP air recovery system |

After the bottle blowing accomplished, high-pressure air can be

recycled can be used again for the pre-blowing and operational

movement.

| 3. Oven and preform temperature detection system |

Real-time detect the temperature of the oven and the temperature of

the preform after

heating before blowing. When the preform heating temperature does

not reach the set blowing temperature blowing workstation will

alarm, not blown.

Characteristics:

1. Controlled by MITSUBISHI touch screen computer. Operate

consistently and simply. |

2. Pneumatic elements from FESTO (German) and SMC (Japan) |

3. Energy-saving and environmentally friendly design. Mechanical

units are compact and rational. |

4. Malfunction alert and diagnostic units allow easy maintenance. |

| 5. Suitable for manufacturing a variety of PET bottles: mineral

water bottles, edible oil bottles, soda bottles, medicine bottle,

cosmetics bottles etc.. |

Technical Parament:

Mold ing | Clamping Force | kg | 12000 |

| Clamping Stroke | mm | 125 |

| Stretching Stroke | mm | 300 |

| Bottom Stroke | mm | 40/70 |

| Cavity Spacing | mm | |

| Number of Cavity | Cavities | 1 |

| Carriage Unit | pcs | 26 |

| Theoretical Output | bph | 800-1000 |

Electrical System | Total Power | kw | 26 |

| Heating Power | kw | 16×1.5KW=24 |

| Number of Lamp Layers | Layers | 8 |

Air System | Operating Pressure | kg/cm2 | 7-9 |

| Lower Pressure Air Consumption | ltr/min | 1600 |

| Blowing Pressure | kg/cm2 | 20-30 |

| High Pressure Air Consumption | ltr/min | 1600 |

Chiller | Operating Pressure | kg/cm2 | 2-4 |

| Temperature Range | ℃ | 10-12 |

| Consumption | kcal/hr | 2000 |

| Flow Rate | ltr/min | 130 |

Main Machine | Main Machine Dimensions | mm(L*W*H) | 1950×1850×2100 |

| Main Machine Weight | kg | 1850 |

Preform Loader | Perform Loader Dimensions | mm(L*W*H) | |

| Perform Loader Weight | kg | |

Option Introduction

- Short mould stroke, quick action.

- Wide adaptability, suitable for every type mould thickness.

- Special design, high rigid compound die structure.

- High responsiveness pneumatic components, action timely and

precisely.

- Small size, low investment. One person enough to operate, simple

and safe.

- Through safe operation mechanism, start-up with two hands, avoid

the accident during the operation.

- Adopt the theory of heat transfer and feedback while designing the

shape and thickness of preform.

- Automatic feeding and automatic dropping the bottles.

- Small size and compact construction with no space waste.

- Adopt special electronic controlling circuit for heating, high

efficiency in simultaneous controlling.

- One lamp or more, lower power consumption.

- The preform will be heated evenly, not be influenced by outside

environment.

Cooling system with cold air cycle ensures same heat exposure of

internal and external surface.

Brand List

| Electrical components | Cylinders |

| PLC | Taiwan Delta | clamping cylinder | Japan SMC |

| touch screen | Taiwan Delta | stretching cylinder | Japan SMC |

| relay | France Schneider | preform-feeding flipping cylinder | Germany FESTO |

| circuit breaker | France Schneider | bottle-takeout flipping cylinder | Germany FESTO |

| air switch | France Schneider | first-stage, second-stage slide cylinder | Japan SMC |

| power supply | France Schneider | heating cylinder | Japan SMC |

| proximity switch | France Schneider | Preform-separating cylinder | Japan SMC |

| photoelectric switch | France Schneider | Manipulator cylinder | Japan SMC |

| |

1. Send you video of the running machine.

2. Welcome to come to visit our factory, see the detail of

machines.

3. Well-trained & experienced staff are to answer all your

inquiries in English and Chinese

| Reliable Customized service |

1. Design the machines according your requirements(material, voltage ,

filling type, various bottles, specially designed device and so on)

.

2. Reliable Professional suggestion, as you know, our company is among

the best in the beverage machinery industry and our engineer has

experience for many years.

3. Design layout for you and offer you advice about machine

orientation or based on the factory area you have.

| Reliable After-sales service |

1. Deliver the machine and provide the B/L on time to make sure you can get

the machine quickly. Also send operating manual and instruction.

2. If you need, our professional engineer team will go to your factory to install

the machine and train your employee until they can operate the

machine well.

3. Regular after-sales calling to remind customers to add the

lubricating oil and maintain machine.

4. Service office in Dubai and other countries and will also visit customers’ factories to check the machines.

5. The machines from Reliable Machinery has one year warranty for free and totally five years life-long technical support.

6. 24 hours for engineer response